Proto

production-quality sample parts

PROTO is a new kind of stamping tool system for production-quality prototypes made to specification and tight delivery schedules.

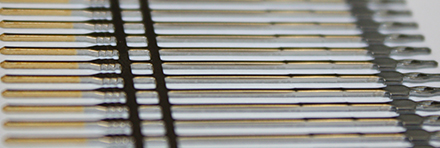

Perfectly synchronized: toolmaking and the subsequent production of stamped parts from a single source. Our progressive combined tools are the best in the world for manufacturing your stamped parts, meeting your specifications with the utmost precision and productivity.

PROTO is a new kind of stamping tool system for production-quality prototypes made to specification and tight delivery schedules.

The MODULAR 1 is a state-of-the-art tool concept offering you a high level of user-friendliness and first-class performance in the low-cost manufacture of short and medium production series as well as for entire product families.

It’s the ideal stamping tool!

Stepper’s high-performance stamping tool for the economic production of large-scale production series of 10 million or more units with an optimal utilization rate. It’s the perfect combination of high precision and high productivity.

The ultimate stamping tool!

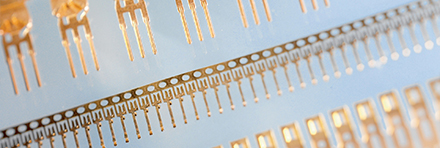

At each stage of a cutting operation. Our computer-integrated production and our top-quality, high-performance stamping tools guarantee the finest results. The extremely long service life of our progressive combined tools ensures the highly economical production of your stamped parts. Our portfolio ranges from high-performance micro stamping tools to stamping grids to the precision stamping tools used in the automotive industry as well as in plastics, electrical, and medical technology. At our in-house stamping workshop we use state-of-the-art machinery (primarily with Bruderer presses) to do small-scale testing or preliminary series as well as full-scale series production.

Like no other, Stepper stands for the efficient production of high-performance stamping tools of outstanding quality. Benefit from our 60 years of experience in making stamping tools and take advantage of our highly professional advice. Feel free to visit us and see Stepper quality firsthand.

The turning point in modern tool design: the Stepper Module System, the first modular stamping tool with an emphasis on user-friendliness.

A universal base tool, which plug-in modules can transform into a custom tool for entire families of parts. With easy operation, minimal maintenance and high speeds, it can handle the most demanding bending, rolling and pressing operations.

Integrated digital workflow, fully automated order planning and data transfer throughout the development, design, manufacturing, assembly and production testing processes. That was the objective Stepper foresaw in the mid-1970s when CAD first came into use in tool manufacturing. The basis of computer-integrated manufacturing is the use of artificial intelligence in the tool manufacturing industry. This is accomplished by a program Stepper developed (a licensed version of which is also available) for the fast and precision design of stamping tools.

Optimal surface treatment in the manufacturing process is just as important, which is why Stepper also takes on this role and conducts intensive research work, quickly turning internally or externally manufactured tools into highly productive tools at its in-house hard surface coating facilities.

With artificial aging, vacuum hardening and other innovative technologies such as Stepper Special Diamond surface coating, for a service life of up to 20 times longer than conventional tools.

The innovative combination of stamping and welding for low-cost production is impressive in every way, completing up to 1,400 multipart, complex precision contacts per minute in a single operation.

Logically implemented in the patented Stepper high-performance combined stamping tool with integrated laser welding module. Or optionally, in the high-performance laser system for hooking up contact components outside the stamping machine.