Proto

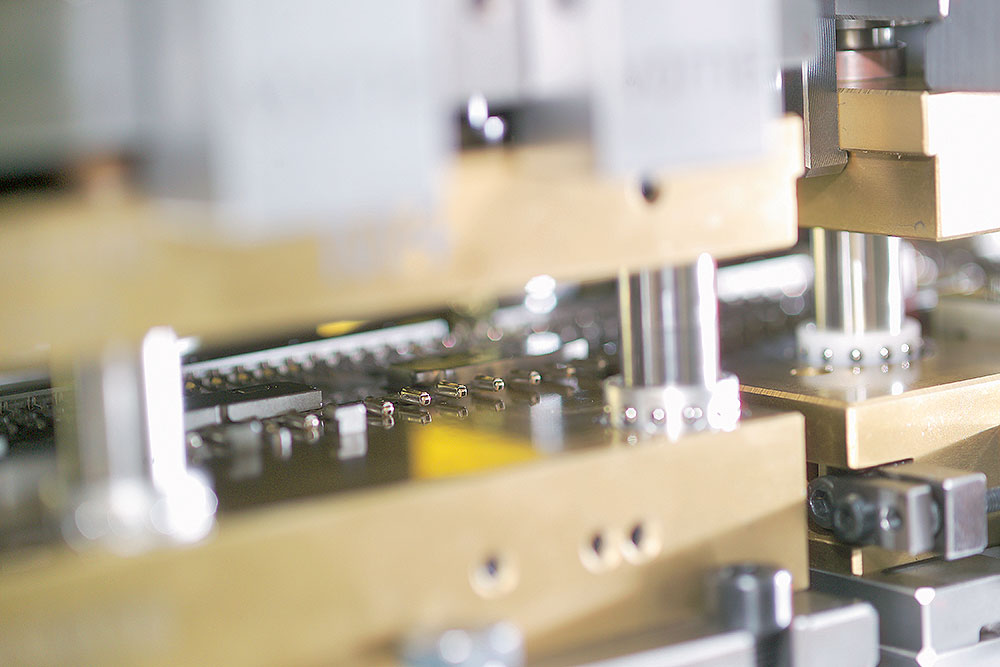

production-quality sample parts

Stepper is your partner from the start of a project to full-scale series production. Take advantage of our 60 years of experience, starting at the product development stage. We are happy to answer your questions, ranging from parts design that meets production requirements to comprehensive finite element analysis (FEM). The PROTO tool system was developed for production-quality prototype sampling – high quality machine-made samples.

Comprehensive test and measuring systems are available, including a research laboratory with a scanning electron microscope (SEM), nanoindenter, scratch tester, kalotester, x-ray and computer tomography.

Production development

We are happy to support and advise you, from your first idea to the finished product. FEM software packages provide accurate evaluation.

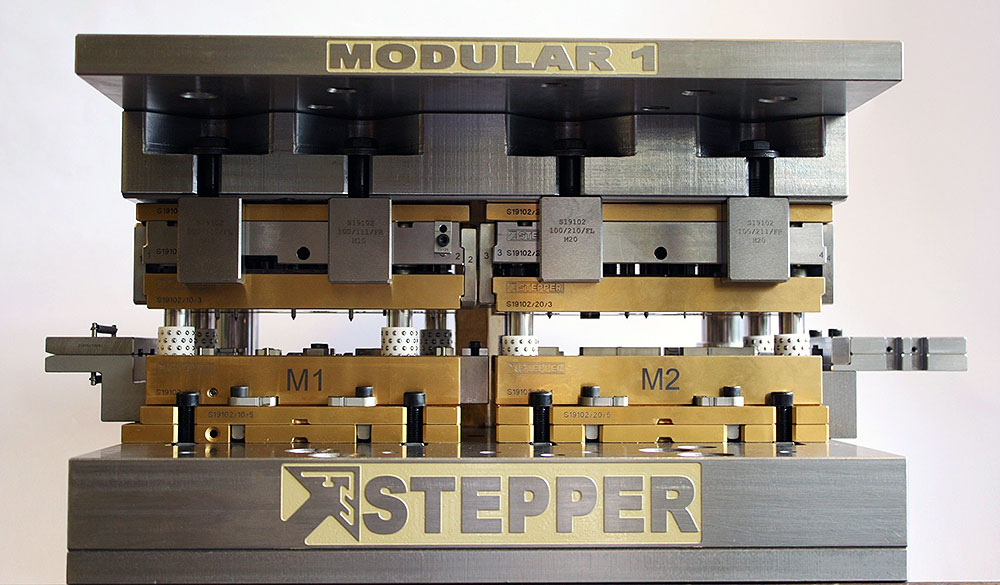

Prototype design = PROTO

Production-quality prototypes for your tests.

Test and measuring equipment

SEM

SEM

Computer Tomograph

Computer Tomograph

Measuring stations

Measuring stations